DeepMPC

Learning Deep Latent Features for Model Predictive Control

Ian Lenz, Ross Knepper, Ashutosh Saxena

Ian Lenz, Ross Knepper, Ashutosh Saxena

For robots to be able to perform the large variety of tasks required of them in the real world, they need to learn layers of abstracted knowledge. Imagine a robot getting your dinner ready for when you come home from work. Sure beats takeout! However, even making a simple recipe like a salad is challenging. There is a huge amount of variety in food items, and each needs to be manipulated differently.

Following traditional control theory, the solution to this problem would be to create a new controller for each food item we want the robot to chop - one for cucumbers, one for lemons, one for potatoes, and so on. Obviously, this is very time-consuming and doesn't let us handle new materials. So much for that bok choy! It also has problems dealing with variations inside the same type of material, like thicker or thinner carrots and potatoes, varying temperature, or layers like the skin and flesh of a lemon.

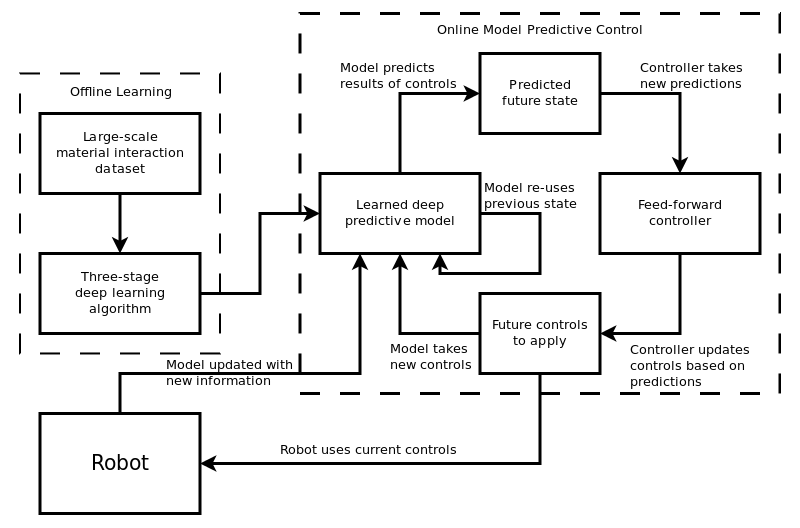

A skilled chef understands from experience how each material responds, and adapts to what he feels while cutting. That's what DeepMPC does, too. It lets the robot learn a model of how the world responds to its actions, even under all the variety we see when cutting food. Then, when acting, it uses this model to pick the actions which it thinks will give the best future results, contiunually updating (100 times a second) based on new information.

Of course, cutting food is just one application of DeepMPC - it's designed to be a flexible, general approach to solving complex control problems where the robot interacts with a changing environment. Other such problems include scrubbing dishes, assembling furniture, manuevering aerial or underwater drones, and even robotic surgery.

More formally, DeepMPC is an approach to model learning for predictive control designed to handle both variations in the robot's enviornment and variations that might occur while the robot acts. The two main components of this algorithm are a Model Predictive Controller (MPC) and Deep Learning (DL).

Model Predictive Control: The key idea behind MPC is essentially allowing a robot to ask "what if?" If we have an accurate model of how the world responds to the robot's actions, it can use this to try new ones out and pick the one it predicts will do best. The problem is that we need an accurate model so these predictions match the real world. Hand-coding models for complex, varying tasks like cutting food is almost impossible, so instead we want the robot to be able to learn from experience.

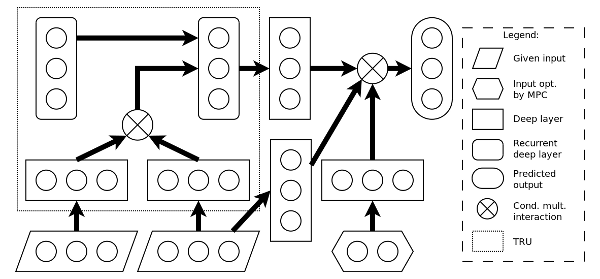

Deep Learning: To learn these models, we apply deep learning algorithms. Deep learning is an exciting new class of machine learning algorithms which learn simulated neural networks to solve problems. These algorithms are especially powerful because they can learn good represntations (abstractions) directly from data, allowing us to deal with real-world variety without having to model it ourselves.

In DeepMPC, we develop a new deep architecture and learning algorithm for modeling complex physical dynamics like we see when cutting food. This architecture allows us to model the effects of variations between and within materials without having to manually define a set of properties to do so. Instead, our algorithm automatically learns a set of features which let the model recognize these properties and predict their effects.

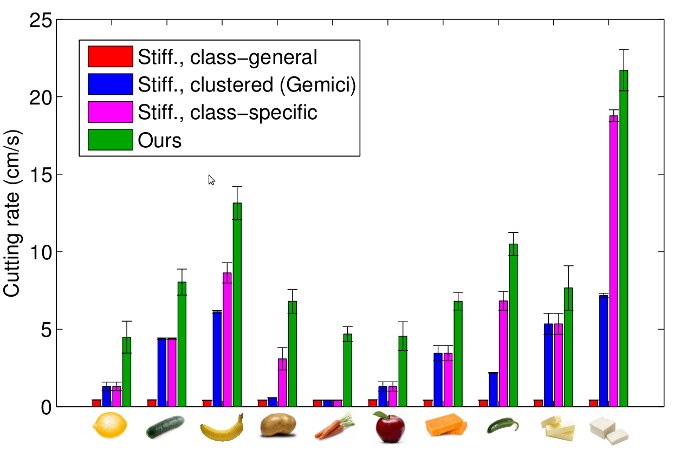

More concretely, we performed over 450 experiments on 10 different materials, comparing our approach to conventional non-adaptive stiffness controllers:

Even compared to stiffness controllers tuned specifically for a particular material, DeepMPC still gave better performance. This is because even per-class tuning ignores all the variation that happens inside a certain class of material - for example, the thin end of a carrot is much easier to cut than the thick end, and cutting a potato gets much harder as the knife moves from the surface to the inside. DeepMPC can detect these kinds of variations and adapt to them while cutting, making for a much more robust controller equipped to deal with real-world variety.